The name SERVOLIFT has stood for innovation, flexibility and quality since 1976. It is associated with a complete offer of handling, blending and cleaning technologies for all areas in pharmaceuticals, chemicals and the food industry. The development and manufacture of blenders, lifters, mobile equipment, containers, cleaning equipment as well as special solutions to meet customer-specific requirements is our job and our know-how.

In close collaboration with customers, depending upon the application, customized projects and machines are planned, sized and implemented. A complete offer provided early to the customer helps to give a visual and functional impression of various designs and their respective benefits. As a complete engineering supplier, Servolift offers everything from simple equipment to complex process units.

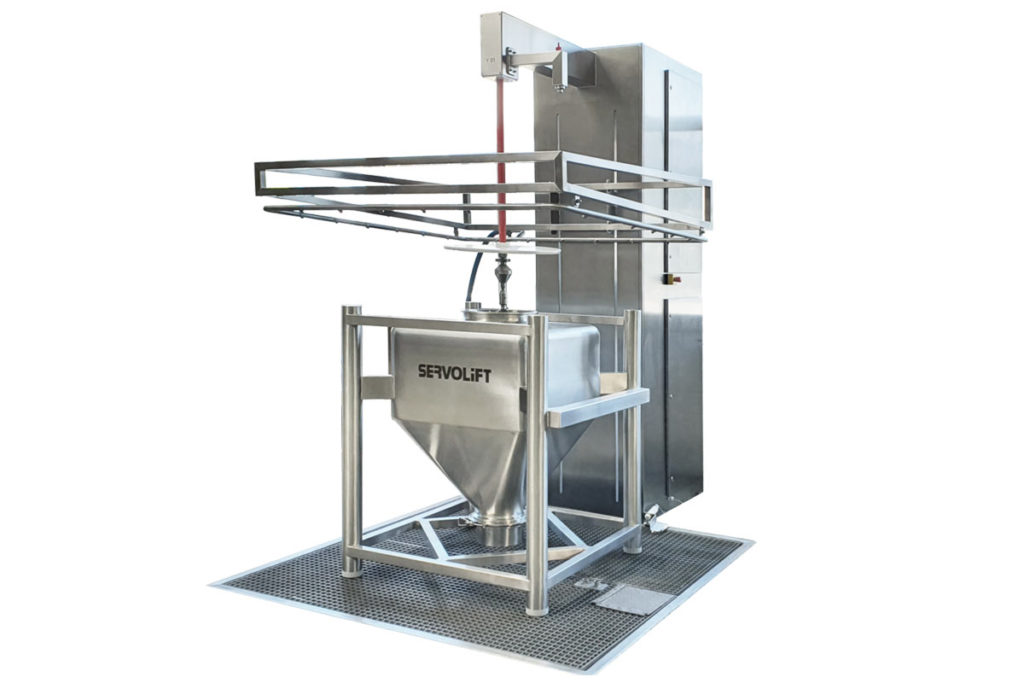

Blending Systems

The mixing of solids means high demands on safety and hygiene in the pharmaceutical production process. In the manufacture of pharmaceutical products, the homogeneity of the mixture produced is a key process step.

Servolift mixers are specially designed for gentle mixing of the product and flexible holding of different containers… The PLC- and recipe-controlled mixing process enables optimum adaptation to the mix. Picking up different container sizes or adapters for drums and small containers can be easily realized by the horizontal Servolift clamping beam system. By extending the handling functions of lifting, lowering, rotating, and swiveling the mixer column, the use of the container mixer can be significantly expanded. This is supplemented by possible add-ons and attachments such as automatic charging and discharging, chopper in the mixing container, spraying system for applying liquids to the mix, upstream and downstream weighing technology, metered discharge, NIR system, etc.

The range extends from laboratory mixers to blending systems with 6,000-liter containers.

Cleaning Systems

The cleaning of parts in contact with the product, such as transport and mixing containers, drums, funnels, components of production plants, etc., is an essential component in the manufacturing process of the pharmaceutical, chemical, cosmetic and food industries. For this reason, Servolift works together with the customer to develop cleaning concepts or systems based on standard solutions that meet the requirements for reproducibility and validation. The basic solutions are washing and drying stations as well as fully automatic single chamber, double chamber cleaning systems. This program is supplemented by small parts cleaning systems and CIP systems.

Filling- and Closing Machine OPTIMA VFVM

Filling- and Closing Machine OPTIMA VFVM Turnkey Solution for Vials with Isolator and Freeze Dryer

Turnkey Solution for Vials with Isolator and Freeze Dryer